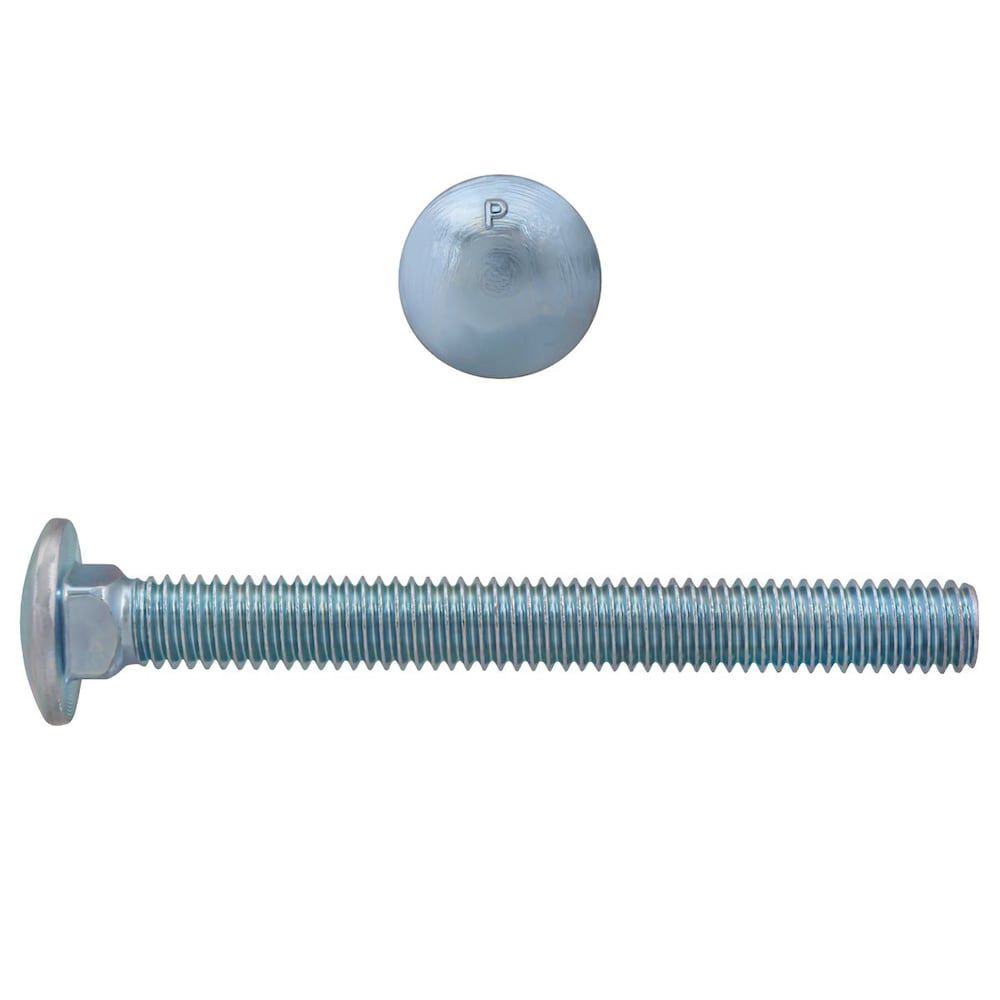

Galvanized or other coated screws are just plain cheaper.ĭespite those drawbacks, the rust prevention is unmatched by other screws. The main benefits of Zinc Plating are that it offers excellent corrosion resistance as it is a sacrificial coating in that the zinc coating slowly corrodes over. It is used to make the metal more corrosion resistant. (2) Stainless steel screws are more expensive. Zinc plated carbon steel offers some rust resistance, hot-dipped galvanized anchors are excellent rust resistors while the 303 and 316 stainless steel fasteners provide superior rust resistance. What is better zinc plated or stainless steel Zinc plating is a process that uses zinc oxide to coat the surface of a metal. You have to slow down and be a little more careful. If the plating is done well over clean metal if will be very corrosion resistant. zinc can be finished raw (silver), black (actually sort of dark green) or gold. It is easier to chew up the heads on stainless screws, or to snap the heads right off by over-torquing them (though that is more of a problem with bolts than wood screws). The plating is a zinc electroplate with a gold irridite finish. You can't just "go crazy" with the power tools and slam the screws into place.

(1) Stainless steel is slightly softer than the hard steel used in deck screws or other similar screws. Why, then, would anyone use anything other than stainless steel outdoors? Two reasons: Most hot-dip galvanized bolts have enough zinc coating to. Stainless steel is undoubtedly the best material for resisting rust and corrosion in screws. The zinc coating has to be thick enough to last until the rust layer forms, usually several years.

Phillips-head screws in particular are notorious for getting ground up when the tip "cams out" and jumps out of the screw head.

DO ZINC PLATED BOLTS RUST DRIVER

I have some screws on an outdoor fence which have rusted inside the slots in the screw head, because the screw driver tip wore away some of the coating in the slots at time of installation. Other screws may be zinc coated as well using another process, or they may be coated with something else. Galvanization is a process that coats with zinc. Galvanized fasteners are best utilized outside where they will resist moisture. Zinc screws can rust and corrode quickly, making them unsuitable for pressure-treated wood. Therefore, I suggest brass plated and copper plated screws for outdoor use. However, it is not as corrosion-resistant as stainless. Zinc-plated screws have good grip and durability, but they are not ideal for outdoor use. The other screws are only covered with a rust-resistant coating on their surface, which will break down or wear off over time. Does zinc coated steel rust Zinc coated stainless steel is a very durable material. Stainless steel screws are rust-resistant throughout the entire screw, not just on the surface. Its main advantage is it is cheaper and easier to weld. While is does provide some rust protection, its thinner coating is not as rust resistant as hot dip galvanising. The stainless steel screw will absolutely be the best screw to resist rust. Zinc plating (also known as electro-galvanising) is a process where zinc is applied by using a current of electricity.

0 kommentar(er)

0 kommentar(er)